-

Home

-

About Us

-

Products

-

Video

-

News

-

Blog

-

Contact Us

Leave Your Message

Request a Quote

The use of Heavy-Duty Plastic Steel Syringes is gaining traction across various industries. According to a recent market analysis by Statista, the demand for durable syringes is projected to grow significantly, due to their effectiveness and reliability. These syringes outperform traditional plastic options in durability and precision. Dr. Michael Thompson, a leading expert in medical device manufacturing, emphasizes, "Heavy-Duty Plastic Steel Syringes are essential for safe and efficient operations."

In medical settings, the potential for contamination is a critical issue. Heavy-Duty Plastic Steel Syringes minimize this risk due to their robust design. Their structural integrity allows for safe handling under pressure, which is vital in emergency scenarios. Yet, concerns remain about the environmental impact of plastic use. We must reflect on balancing efficiency with sustainability while utilizing Heavy-Duty Plastic Steel Syringes.

The healthcare sector’s reliance on reliable tools shapes patient outcomes. As industries adapt, the need for comprehensive evaluations of products grows. Heavy-Duty Plastic Steel Syringes stand out, yet continuous improvement is necessary. This way, we ensure that these essential tools meet the highest standards while considering our ecological footprint.

Heavy-duty plastic steel syringes serve a variety of applications across different industries. They are widely used in medical settings for delivering precise dosages of medication. These syringes are designed to withstand harsh conditions, making them suitable for both liquid and viscous materials. The sturdy construction ensures reliability and durability during use. However, some users may find them difficult to handle when a high level of precision is required.

In laboratories, heavy-duty syringes can be indispensable for transferring fluids. They can also be utilized for mixing samples in various chemical processes. The clear markings on these syringes allow for accurate measurements. But, it’s worth noting that the syringes can sometimes leak if not properly maintained. Regular cleaning and inspection are necessary to avoid such issues.

Another aspect to consider is their environmental impact. While these syringes are designed for repeated use, not all are recyclable. Users should be aware of their disposal methods. Taking care of these syringes extends their lifespan, but improper disposal can lead to waste. It's always important to reflect on how these tools affect both efficiency and sustainability.

| Feature | Description | Applications |

|---|---|---|

| Durability | Made from heavy-duty plastic and reinforced steel, ensuring long-lasting use. | Industrial applications where robust equipment is essential. |

| Chemical Resistance | Resistant to a wide variety of chemicals, making them suitable for lab settings. | Pharmaceutical and chemical industries. |

| Precision | Designed for accurate measurements with clear markings. | Medical and research applications requiring precise dosing. |

| Ease of Use | User-friendly design for easy filling and dispensing. | Veterinary use and manufacturing processes. |

| Cost-Effectiveness | Affordable compared to metal syringes, providing a budget-friendly solution. | General purpose use in labs and production lines. |

Heavy-duty plastic steel syringes have become essential tools across various industries. Their robust construction provides durability, making them ideal for demanding environments. In agriculture, for instance, these syringes can withstand the rigors of animal vaccination. They are easy to clean and sterilize, which is crucial in maintaining health standards.

In the food industry, these syringes help with precise ingredient measurement. They ensure accuracy, leading to better product quality. However, users must consider their proper handling. Misuse can lead to spills or miscalculations, affecting production. The challenge lies in training staff effectively to avoid such errors.

Additionally, heavy-duty plastic steel syringes are lightweight, allowing for easy transportation. This brings flexibility but can also lead to overpacking during shipping. Striking a balance is necessary. Overall, the benefits are substantial, but attention to detail is critical in maximizing their effectiveness.

This chart illustrates the rating of various key advantages of heavy-duty plastic steel syringes across different industries. The ratings reflect durability, chemical resistance, cost-effectiveness, user-friendliness, and versatility.

Heavy-duty plastic steel syringes offer remarkable durability. They are designed to withstand high levels of stress and use. This makes them suitable for various applications, from medical fields to industrial use. Their robust construction ensures they resist damage from impacts and drops. This feature enhances their reliability, which is crucial in critical situations.

Another key aspect is their resistance to chemicals. Heavy-duty syringes can handle a wide range of substances without degrading. This capability is particularly beneficial in laboratories and workshops. Users can carry out tasks without worrying about contamination or material breakdown. However, it is important to regularly check for wear and tear, even with these resilient tools. Over time, exposure to harsh environments might compromise performance.

The anti-corrosive nature of these syringes also deserves attention. They can maintain their integrity in difficult conditions. This resistance helps avoid costly replacements and ensures continued efficiency. Nevertheless, improper cleaning can lead to issues. Users must adopt a disciplined cleaning regimen to fully leverage their advantages. Careless handling can negate the benefits that heavy-duty plastic steel syringes provide.

Heavy-duty plastic steel syringes offer significant health and safety benefits. They are designed to withstand rigorous use, making them ideal for various applications. These syringes minimize the risk of breakage, which can lead to exposure to harmful substances. The sturdy materials reduce potential injuries, ensuring safer handling.

In healthcare settings, safety is paramount. Heavy-duty syringes maintain strict hygiene standards. Their non-porous surfaces prevent contamination, fostering a cleaner environment. Additionally, they can be easily sterilized and disposed of, further enhancing safety. The durability of these syringes often translates to cost-effectiveness as well.

However, it's essential to reflect on the proper disposal methods for these syringes. Improper disposal can still pose environmental risks. Users often overlook this crucial step. Awareness regarding safe disposal is vital for maximizing benefits. Each user must take responsibility for their actions in safeguarding health and the environment.

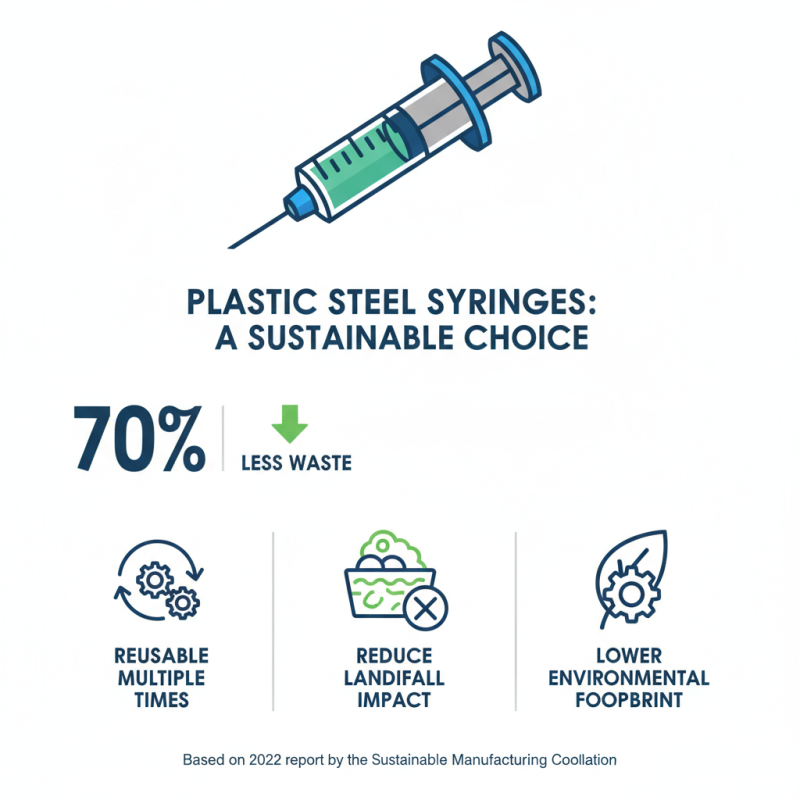

Heavy-duty plastic steel syringes offer a promising option for sustainable practices in various industries. Their robust design means they can be reused multiple times, reducing the demand for single-use syringes. According to a 2022 report by the Sustainable Manufacturing Coalition, reusable products can reduce waste by up to 70% compared to single-use alternatives. This significant reduction directly impacts our landfills and helps lower overall environmental footprints.

The materials used in these syringes also make a difference. While traditional plastics can take centuries to decompose, heavy-duty plastic steel blends offer improved longevity and recyclability. A study by the Eco-Friendly Innovations group shows that recycling these materials can reduce greenhouse gas emissions by approximately 30%. However, it’s essential to note that the recycling rates for such materials still lag behind expectations. Only about 15% of plastic syringes are currently recycled effectively. This indicates a critical area for improvement in our waste management systems.

As industries shift towards heavier reliance on these syringes, awareness and education become vital. Manufacturers and consumers must recognize the importance of proper recycling methods. While heavy-duty syringes present benefits, the infrastructure for handling post-use products is often inadequate. The need for better systems reflects a gap in our sustainability efforts. Addressing these challenges is crucial if we truly aim for a greener future.